EPE Recycling Solution

EPE is widely used in shockproof packaging of electronic items, offering both durability and flexibility. GREENMAX MARS foam densifier machines can compress EPE foams into dense blocks, the compression ratio reaching at 90:1, which can be reused to be EPE products and PE packaging.

Expanded Polyethylene (EPE), also is known as pearl cotton. At present, EPE foam is the most advanced protective inner packaging material which has high elasticity. EPE is a new type of environmentally friendly packaging material.

The superior properties of EPE foam and its ability to absorb large amounts of impact make it a necessity when handling and transporting products. EPE is mainly used in packaging and buffering materials for ceramics, light electrical appliances, precision machinery parts and building materials, as well as in the insulation of roofs and air conditioners.

As an environmentally friendly material, EPE can be recycled and reused. GREENMAX has many years of R&D and practical experience in the field of foam recycling. It has developed the GREENMAX foam recycling machine to compress EPE foam into dense blocks for easy transportation and storage. When a large piece of EPE foam is put into the GREENMAX machine, it will be crushed into pieces by the screw and fall into the silo at the bottom. Then, it will be compressed by the machine into EPE blocks and extruded by a screw, which can be sold directly to manufacturers to make products, such as extrusion products, film blowing products and so on. After the granulation process, these foam blocks will become EPE foam pellets, which can be made into other recycled products.

-

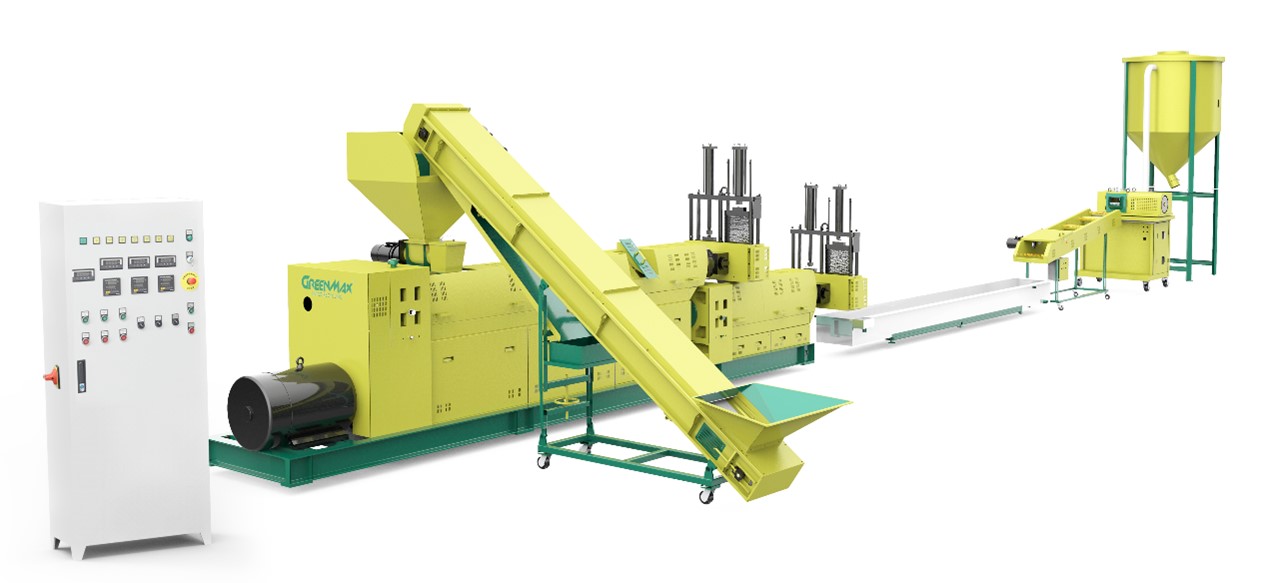

GREENMAX Foam Pelletizer

GREENMAX Foam Pelletizer can turn compacted EPE blocks into pellets for the production of environmentally friendly recycled products. The entire production process is highly automated, saving manpower and costs. The pelletizer can be used independently or integrated into a complete system with other machines such as crushers and compactors.

-

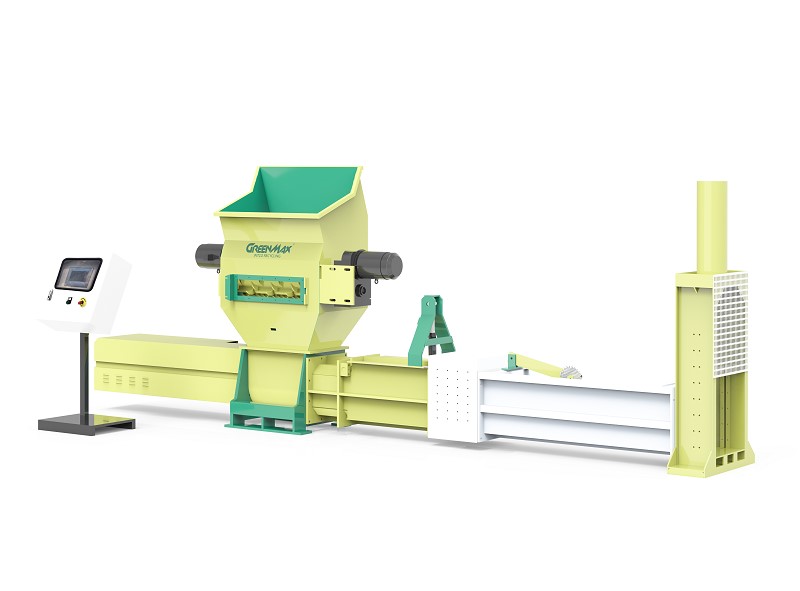

GREENMAX Foam Densifier MARS Series

GREENMAX MARS Foam Densifier is specifically designed to melt and densify foam into a more compact and manageable form. The machine works by heating EPE foam at high temperatures, causing it to melt and compress into smaller, denser pieces that take up less space and are easier to transport, store and process.

-

GREENMAX Foam Compactor ZEUS Series

GREENMAX ZEUS Foam Compactor has surface melting technology, which can heat and melt the surface of the compacted EPE to prevent expansion and loosening inside the foam. The GREENMAX machine can compress foam to one-fiftieth of its original volume, providing great convenience for subsequent transportation, granulation and reuse.