EPP Recycling Solution

EPP foam as a kind of security and environmental-friendly material can be applied in car parts and packaging. GREENMAX Recycling System convert EPP foams into blocks and pellets that can be sold to GREENMAX and reused to PP products.

As a safe and environmentally friendly material, expanded polypropylene (EPP) is easy to recycle and used in many fields such as automobiles, construction, and logistics. EPP offers a range of unique properties, including impact resistance, thermal insulation, buoyancy, waterproofing, and chemical resistance.

EPP foam is widely used in various applications in the automotive sector, including bumpers, door panels, and instrument panels, and its demand continues to increase. For automakers, EPP is an excellent choice for reducing vehicle weight and improving fuel efficiency due to its lightweight, toughness, and impact resistance.

In fact, it is 100% recyclable and the whole process is easy with the help of professional EPP recycling machines.

The GREENMAX EPP recycling machine can compress EPP into ingots, which can be sold to manufacturers to be remade into other products. The waste EPP is biaxially crushed and then heated at high temperatures or physically compressed to form dense EPP ingots or blocks. After the process of crushing and granulation, these foam scraps will become EPP pellets, which can be made into other recycled products.

-

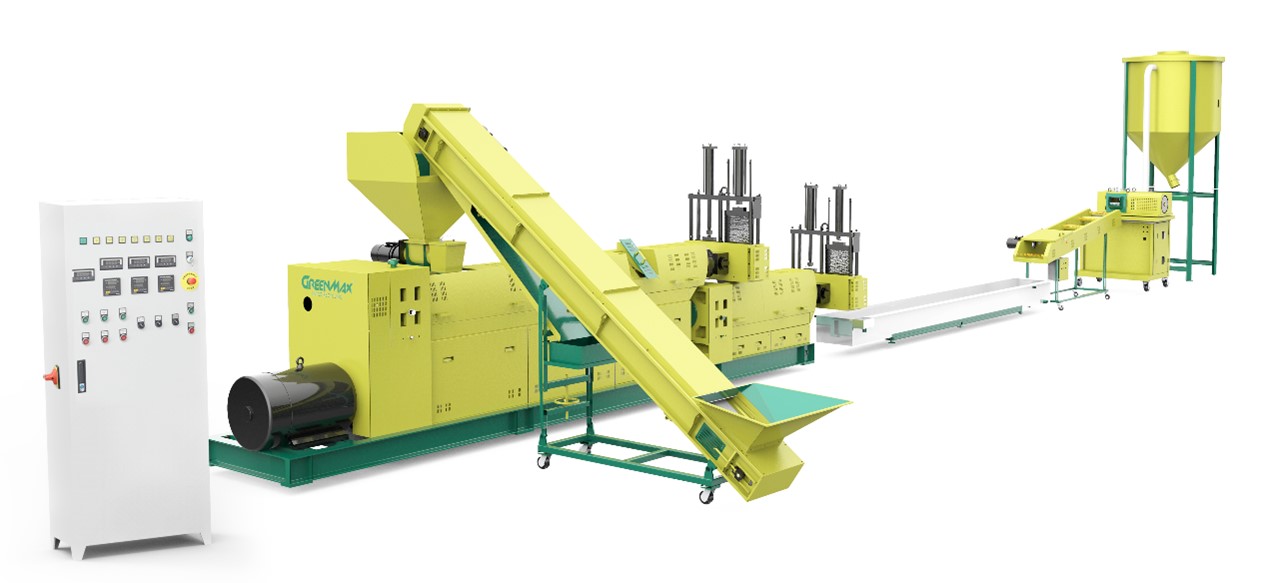

GREENMAX Foam Pelletizer

GREENMAX foam pelletizer produces foam pellets, which are used to manufacture various injection products. Waste EPP foam undergoes processes such as compression, crushing, and granulation, and finally becomes pellets. GREENMAX provides customized design services. This pelletizer can be used independently or integrated into a complete system with crushers and compactors, or even integrated into washing system.

-

GREENMAX Foam Hydraulic Compactor

GREENMAX foam hydraulic compactor is a foam recycling machine that specializes in crushing and compacting foam into blocks through hydraulic pressure. It does not require heating and is very energy-saving. The machine is equipped with a high-efficiency automatic hydraulic system to compress EPP waste at a ratio of 70:1, greatly saving storage and transportation costs. The hydraulic press is highly automated, and one person can complete the entire operation process with low labor costs.

-

GREENMAX Foam Densifier MARS Series

GREENMAX MARS foam densifier has screw melting technology that can compress EPP foam at a ratio of 90:1. After the machine crushes the foam, the foam is heated and melted in the screw through the conveying and extrusion of the screw, and finally it is extruded through the discharge port and formed. Compressed EPP ingots are easy to transport and store, which can save a lot of costs.