Foam Recycling Line

EPC project case of recycling EPS waste foam and producing XPS insulation boards:

Project Name: Waste foam recycling EPC project in a city

Project Scale:Designed annual production capacity of 100,000 cubic meters of XPS insulation boards

Project Content: including waste foam recycling system, XPS insulation board production system, waste gas treatment system, etc.

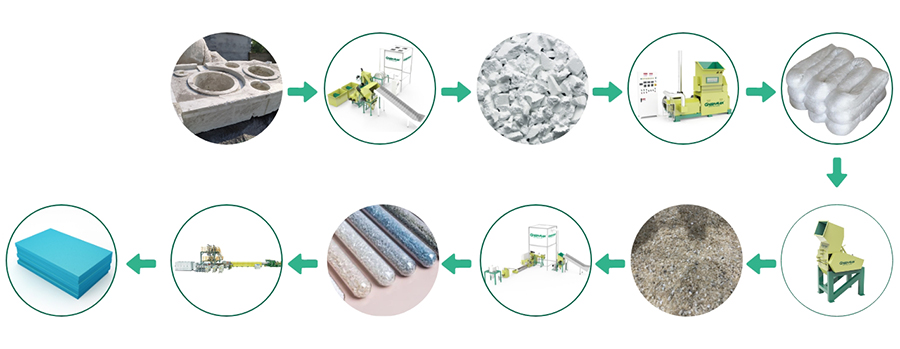

Project Flows:

1. EPS waste foam sorting and cleaning: First, the collected waste foam is selected and sorted, and then enters the GREENMAX Triton series cleaning system. The dirty waste foam is crushed, washed and dried into clean EPS foam crushed material.

2. EPS foam volume reduction: The cleaned foam crushed material is hot melted and volume reduced through the GREENMAX Mars series hot melting machine, with a volume reduction ratio of 90:1. After the melt is cut, water-cooled, and automatically bagged, the EPS spherical hot melting block can enter the next step of the granulation process.

3. EPS hot melting block crushing: The spherical hot melting block is crushed by the GREENMAX Reha series crusher into a size of 10mm-20mm.

4. EPS hot melting block granulation: The hot melting block crushed material is then granulated through the GREENMAX G series pelletizer to create high-quality recycled particles.

5. XPS board extrusion: EPS recycled particles are processed by GREENMAX XPS board extrusion equipment and CO2 foamed to produce high-quality, environmentally friendly XPS insulation boards.

In this EPC project case, GREENMAX took on the responsibility for the entire process from engineering, procurement to construction, which is conducive to the quality control and progress management of the project. The highlight of this project is to turn low-value EPS foam waste into high-value-added XPS building insulation materials through an efficient recovery, regeneration and utilization system, forming a closed loop of turning waste into treasure and low-carbon cycle.