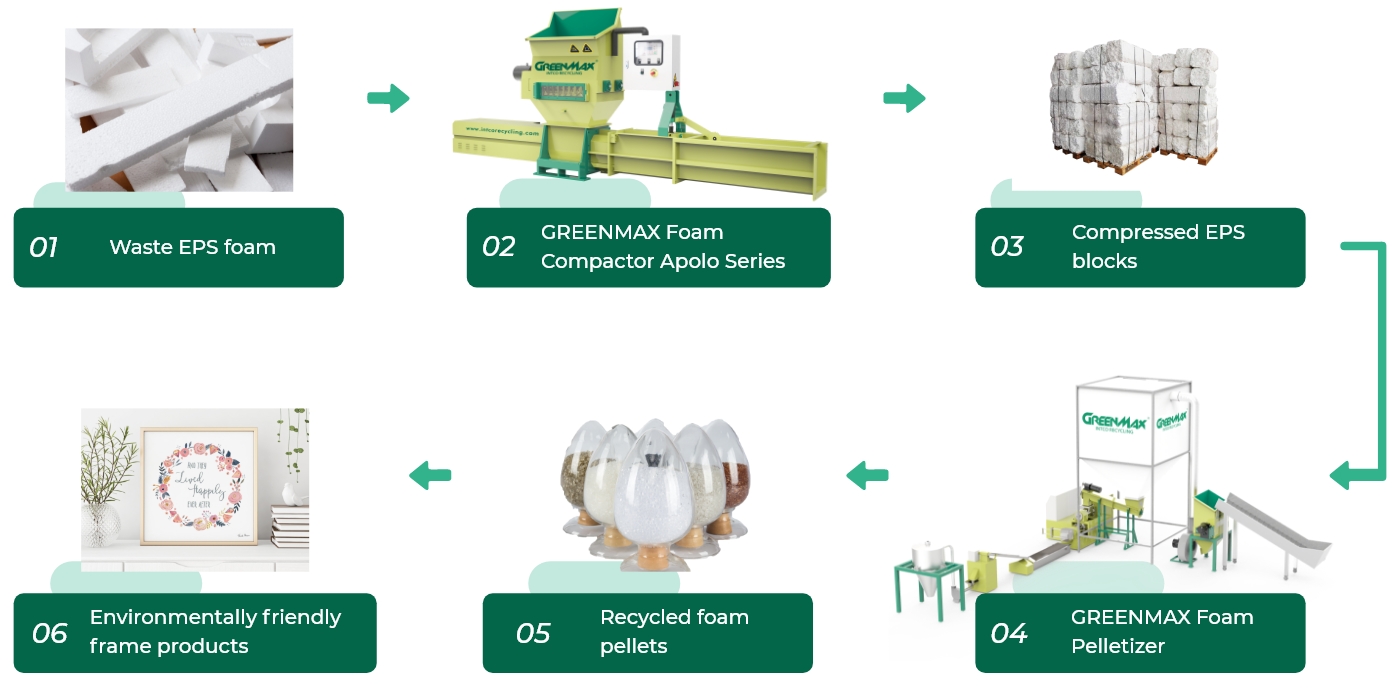

EPS Recycling Solution

EPS foam is bulky and lightweight, but EPS is recyclable. GREENMAX foam compactor machines can compress EPS foams to 1/50 and 1/90 of their original volume. We repurchase foam blocks.

Expanded polystyrene (EPS) is made from non-renewable resources such as oil and natural gas and is not biodegradable. EPS is used in a wide range of applications, but is often treated as a disposable product and ends up in landfills. However, EPS is recyclable.

EPS is durable, shock-absorbing, moisture-proof, and insulating, making it suitable for protecting products during transportation and storage. Common household appliances, instruments, handicrafts, fast food, and other packaging are all packaged in EPS.

GREENMAX recycles, crushes and compresses EPS waste into compact foam blocks through EPS recycling machine. Afterwards, through the granulation process of the pelletizer, these foam blocks will be turned into pellets, and finally made into environmentally friendly frames, mouldings and exterior wall insulation materials, not only saving natural resources but also reducing carbon dioxide emissions. GREENMAX machine can make the EPS recycling process simple, safe and efficient.

GREENMAX provides a complete set of EPS recycling solutions and recycling machines to customers around the world and provides EPS waste repurchase services.

-

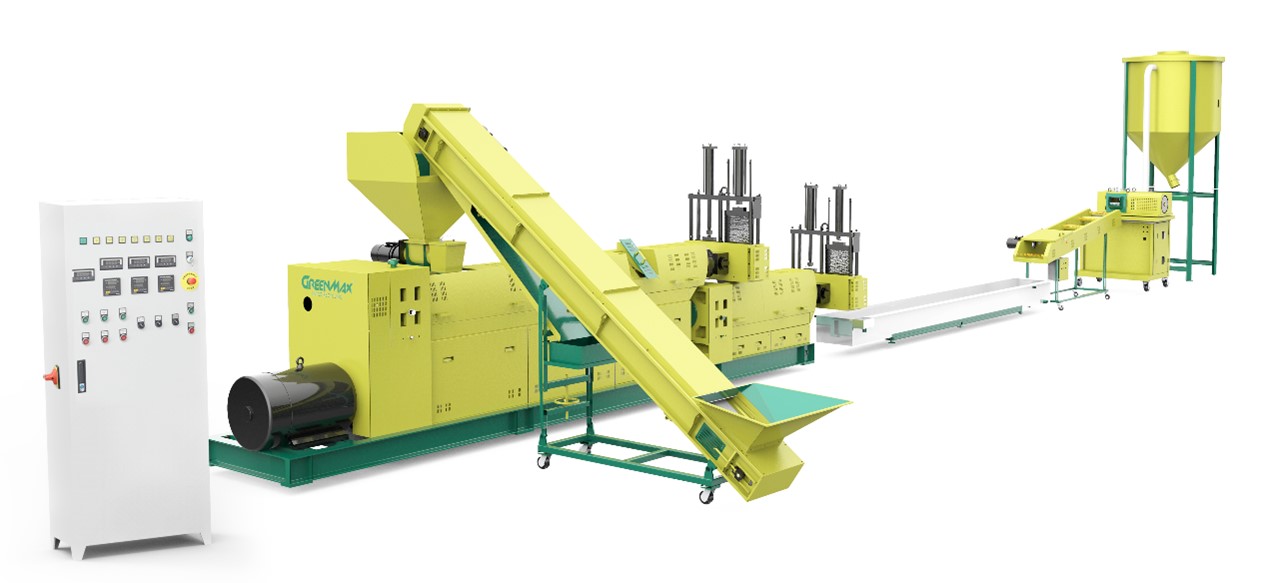

GREENMAX Foam Pelletizer

GREENMAX Foam Pelletizer produces foam pellets which have many application, such as environmentally friendly fames, mouldings and construction boards. Waste EPS foam goes through processes such as crushing, melting, extruding, cooling and granulation, and finally becomes pellets. GREENMAX offers customized design services, and this pelletizer can be used independently or integrated into a complete system with crusher and compactor, or even integrated into washing system. The entire production process is highly automated, saving manpower.

-

GREENMAX Foam Densifier MARS Series

GREENMAX MARS Foam Densifier screw melting technology enables continuous output of 90:1. As the machine crushes the EPS foam, the foam is heated and melted in the screw through the conveying and extrusion of the screw. And finally, it is extruded through the discharge port and formed. It's simple to operate, just change the temperature without any extra steps in the process. The machine is easy to maintain 5S, and there is little spillage of EPS foam debris.

-

GREENMAX Foam Compactor ZEUS Series

GREENMAX ZEUS Foam Compactor has unique surface melting technology, which can heat the surface of the compacted EPS foam to melt it and prevent internal expansion and loosening. This series is equipped with a heavy-duty crusher, which is capable of breaking EPS into small pieces of 20-50 mm size. The machine compresses the foam at a ratio of 50:1, providing great convenience for the recycling, transportation and reuse of waste foam.

-

GREENMAX Foam Hydraulic Compactor

GREENMAX Foam Hydraulic Compactor specializes in crushing and compressing EPS foam into blocks at a ratio of 70:1 through hydraulic pressure. The machine is equipped with a high-efficiency automatic hydraulic system, saving storage and transportation costs. The labor cost required by this hydraulic compactor is low, and the entire system is very intelligent.

-

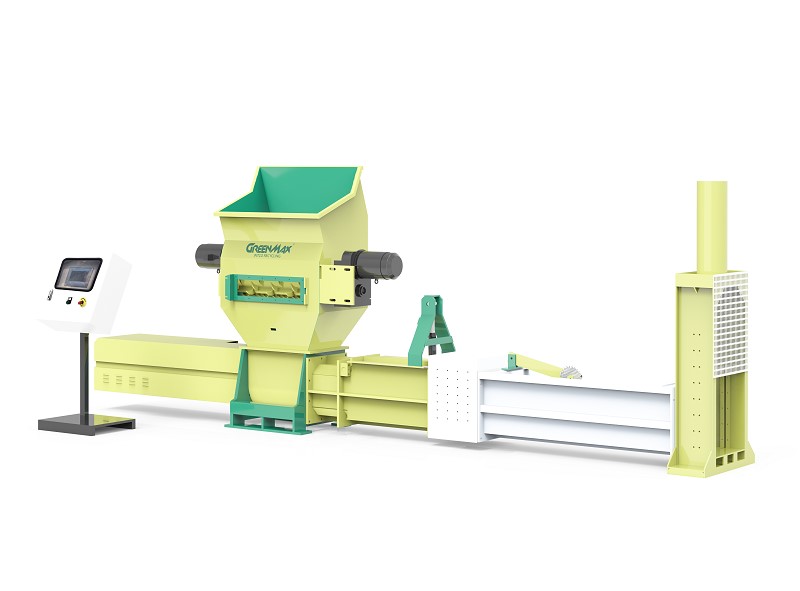

GREENMAX Foam Compactor APOLO Series

GREENMAX APOLO Foam Compactor can crush EPS through blades and gears, and compress EPS foam into tight blocks through physical extrusion of the screw. These EPS foam blocks are compressed to one-fiftieth of their original volume, reducing transportation and warehousing costs. This series of foam compactors can handle foam boxes containing water, such as fish boxes, etc.