Plastic granulators play a crucial role in recycling by transforming plastic waste into reusable material, thereby reducing the environmental impact of plastic pollution. Plastic granulator/pelletizer is a machine used to break down plastic products into smaller, more manageable pieces or granules. This process is essential in plastic recycling and waste management.

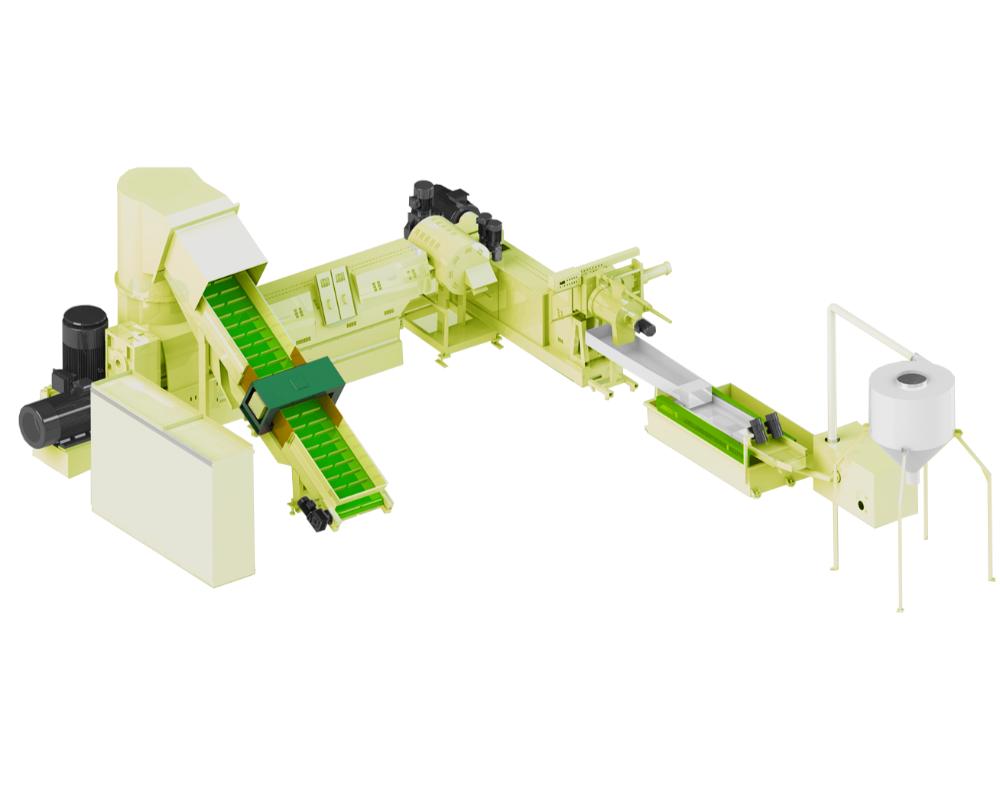

Here's a detailed explanation of how a GREENMAX plastic granulator works:

At first, plastic waste is fed into the granulator through the hopper. The hopper is designed to accommodate various shapes and sizes of plastic waste.

Then, as the motor powers the rotating blades, they spin at high speed within the cutting chamber. The plastic material is forced against the fixed blades, creating a shearing action that cuts the plastic into smaller pieces. The continuous cutting and shearing action between the rotating and fixed blades reduce the plastic waste into granules. The size of the granules is determined by the screen. Only pieces small enough to pass through the screen will exit the cutting chamber.

At last, the screen ensures uniform granule size by allowing only granules of a certain size to pass through. Larger pieces that cannot pass through the screen remain in the cutting chamber for further granulation.The granulated plastic is collected in the discharge area or container. These granules can then be further processed, melted down, or used in the production of new plastic products.