Recycling plastic waste into reusable materials is a key component of effective waste management. One of the most efficient methods for achieving this is by using a GREENMAX pelletizing machine. If you’re interested in transforming plastic waste into valuable pellets, here's a comprehensive guide on how to do it with a GREENMAX pelletizing machine.

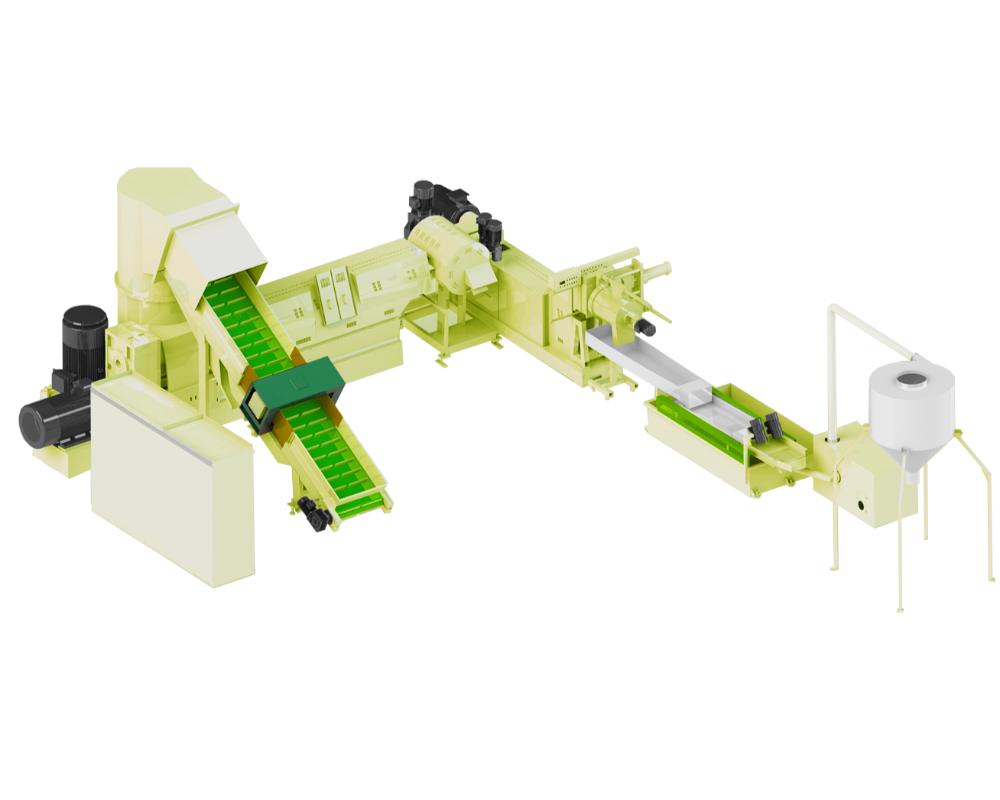

GREENMAX is a specializing in advanced recycling technology, including pelletizing machines designed to process plastic waste. Their machines are engineered to handle a variety of plastics and turn them into high-quality pellets, which can be used in manufacturing new products. The GREENMAX pelletizing machine offers efficient, high-performance solutions with features that streamline the recycling process.

Step-by-Step Guide to Turning Plastic Waste into Pellets

1. Shredding

Plastic waste needs to be shredded into smaller pieces, or flakes. This step is essential for making the plastic easier to handle and process. You can use a shredder or granulator to break down the plastic into manageable sizes.

2. Drying

Next, dry the plastic flakes thoroughly to remove any remaining moisture. Moisture can interfere with the melting process and affect pellet quality. Ensure that the flakes are completely dry before moving on to the next step.

3. Feeding into Pelletizing Machine

Load the dried plastic flakes into the GREENMAX pelletizing machine. The machine’s feeder will introduce the flakes into the extruder, where they will be melted. The GREENMAX machine is designed to handle different types of plastics and has adjustable settings to optimize the melting process.

4. Extrusion

In the extruder, the plastic flakes are heated and melted under controlled conditions. The GREENMAX pelletizing machine uses precise temperature and pressure settings to ensure that the plastic is melted uniformly. The melted plastic is then pushed through a die to form continuous strands.

5. Cooling and Cutting Pellets

The continuous strands of melted plastic are cooled, typically using a water bath. After cooling, the strands are cut into small, uniform pellets. The GREENMAX pelletizing machine is equipped with a cutting mechanism that ensures the pellets are consistent in size and shape.

Turning plastic waste into pellets with a GREENMAX pelletizing machine is a highly effective way to contribute to sustainability and manage plastic waste. If you’re ready to take your recycling efforts to the next level, consider incorporating a GREENMAX pelletizing machine into your process. It’s a powerful tool that makes turning plastic waste into valuable pellets more efficient and effective than ever.uture.