In the world of recycling and manufacturing, plastic pelletizing machines play a crucial role. They transform plastic waste into valuable pellets that can be used in new products. Here' s a deep dive into how these machines work and why they are essential.

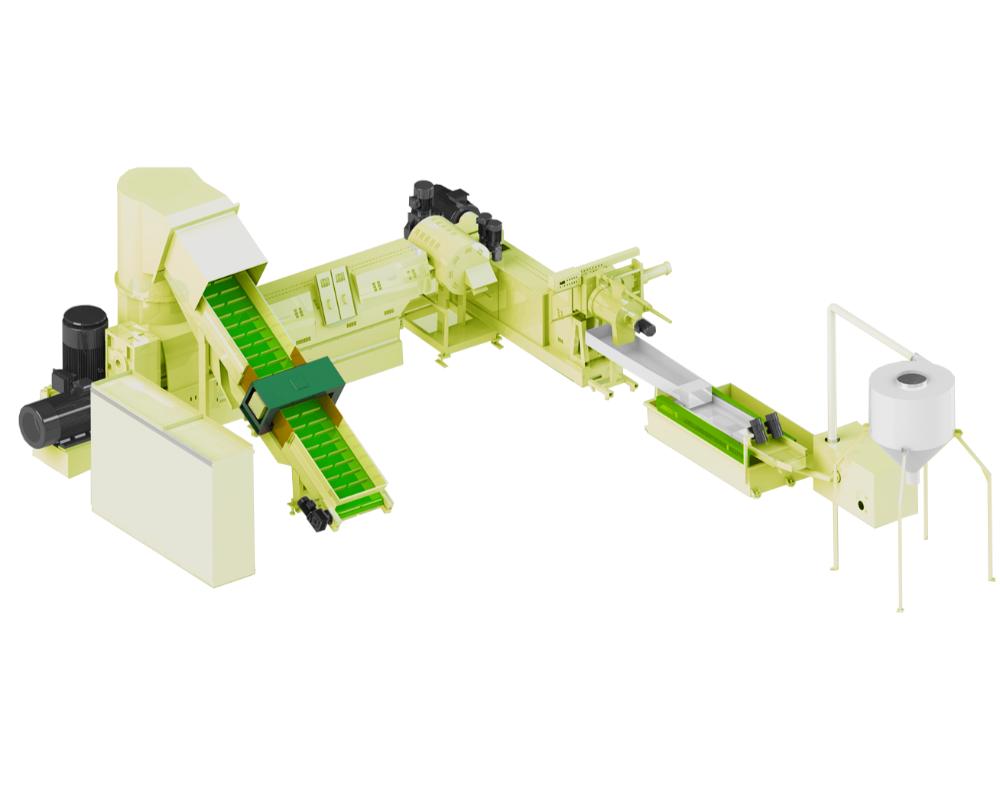

Plastic pelletizing is the process of converting plastic waste into small, uniform pellets. These pellets can be used as raw material in various manufacturing processes. Plastic pelletizing machine typically involves several stages: feeding, melting, extrusion, cooling, and pelletizing. GREENMAX plastic pelletizing machine is a key player in the recycling industry, designed to convert plastic waste into high-quality pellets.

Feeding the Plastic

The process begins with feeding plastic waste into the machine. This waste can be in various forms, including flakes, granules, or shredded pieces. The choice of feed material depends on the type of plastic and the machine’s design.

Melting the Plastic

Once the plastic is fed into the machine, it enters the extruder. The extruder consists of a screw mechanism that moves the plastic forward while applying heat. This heating process melts the plastic, turning it into a viscous, molten state. The temperature and speed must be carefully controlled to ensure consistent melting and prevent degradation of the material.

Extruding the Melted Plastic

The molten plastic is then forced through a die, which shapes it into long, continuous strands or filaments. The die is designed to create specific shapes and sizes of extrudate. This stage is critical as it determines the initial form of the plastic before it is cut into pellets.

Cooling the Strands

After extrusion, the plastic strands need to be cooled to solidify them. This is typically done using either a water bath or air cooling system. In a water bath, the strands are passed through a tank of water that cools and hardens them quickly. Air cooling involves blowing air over the strands to achieve the same result. Cooling must be uniform to ensure the consistency and quality of the final pellets.

Pelletizing the Plastic

Once cooled, the solidified strands are cut into small, uniform pellets. This is done using a pelletizer, which can be equipped with rotating blades or cutters. The size of the pellets is determined by the cutter settings and can be adjusted based on the desired specifications. Proper pelletizing ensures that the pellets are of consistent size and quality, which is crucial for their further use in manufacturing.