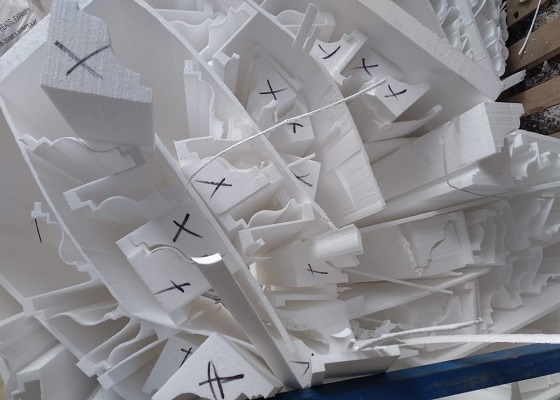

ARQUIPOR, a leading manufacturer of EPS products in Guatemala, has successfully addressed the challenge of EPS foam scraps in their production process by partnering with GREENMAX. Known for producing high-quality EPS building materials and decorative products, including EPS moldings and columns, ARQUIPOR faced significant waste management issues due to the accumulation of EPS cut-offs.

In 2020, ARQUIPOR invested in the EPS foam densifier M-C200 from GREENMAX, a move that revolutionized their waste management practices. This GREENMAX foam recycling equipment compresses EPS foam scraps, making them easier to handle and recycle. The collaboration began when a friend in Mexico recommended INTCO Recycling, highlighting GREENMAX dual role as a recycling equipment manufacturer and an EPS foam recycler. This partnership not only solved ARQUIPOR's waste EPS problem but also allowed them to sell recycled foam blocks back to GREENMAX for the production of new foam products.

The Guatemalan government's push for waste recycling and landfill reduction aligns perfectly with ARQUIPOR's sustainability goals. The company plans to expand its recycling efforts beyond its factory, aiming to collect and recycle commercial EPS waste across Guatemala. This initiative will help raise awareness about the recyclability of EPS foam and promote sustainable practices nationwide.

By adopting GREENMAX EPS foam densifier, ARQUIPOR is leading the way in sustainable manufacturing and waste management in Guatemala.