One customer is a waste recycling company in Indonesia. It operates MRF facilities (materials recovery facilities) in Ambon and Makassar. Since July 2022, they have started supplying pressed bottle bale to Intco Recycling and are our important strategic supplier in eastern Indonesia.

The customer has been using a vertical baler purchased locally in Indonesia. The machine's baling power is relatively low, and the baling size is not fully suitable for 40HQ container loading. Therefore, the average container weight of other Indonesian suppliers is 14 to 15 tons. This has resulted in the customer's transportation cost being very high. Whether they are cooperating with our company or competing with local companies, they are at a disadvantage. The customer sought a better PET bottles recycling solution from our company and urgently needed to increase the loading weight, reduce transportation costs, and achieve fully mechanized and efficient loading.

The customer knows that INTCO Recycling local procurement volume has been growing steadily overall, and is relatively familiar with the characteristics and recycling model of Indonesian pressed bottle bale. At the same time, we has our own machinery brand GREENMAX, so after understanding our company's baler business, he decisively placed a single horizontal PET bottles baler and three vertical PET bottles balers. He hoped that we could help him provide a more efficient baling solution based on his specific situation and implement it as soon as possible. After we confirmed the order, delivered four balers including conveyor belts as scheduled.

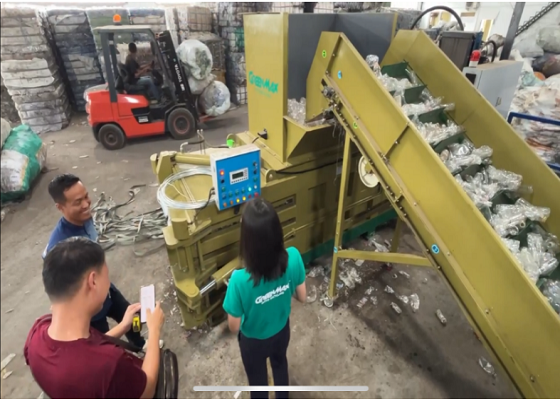

After the customer receives the machine, we provided usage guidance services as soon as possible. At the same time, based on the actual conditions observed at the customer's factory site, we will make reasonable optimization suggestions for the layout and planning of the customer's recycling plant. The customer is not only able to use the GREENMAX baler proficiently, but also makes more scientific adjustments to the layout of the factory.

The production efficiency is greatly improved, the container weight is also significantly improved, and the transportation cost is greatly optimized. The customers think that our recycling closed loop is very complete and mature, and highly recognize it, so they have been working closely with us. Not only that, our suppliers have been steadily increasing, and we have achieved win-win cooperation with more factories in the industry, helping more customers have solved the problem of PET bottles recycling, saving and reducing costs, getting twice the result with half the effort, and greatly increasing the profit margin of raw materials!